November 22, 2024

Learn more about our Early Development offering

Expert Support at Every Stage from Candidate Selection through Phase 1

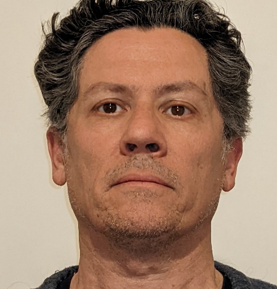

Senior Director, Chemistry, Manufacturing, & Controls

Dr. Shah leads Certara’s CMC team with over two decades of experience in formulation development, drug delivery, and regulatory interactions.

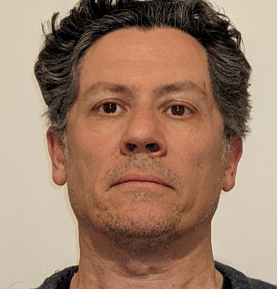

Senior Scientific Advisor & Head of Mechanistic Oral Absorption Modelling

David B. Turner PhD is a Senior Scientific Advisor and Head of Mechanistic Oral Absorption Modelling at Certara UK Ltd (Simcyp Division) having joined Simcyp in 2004. He is author or co-author on 45+ publications.

For questions about this presentation, please contact our experts.

Solubility

Solubility